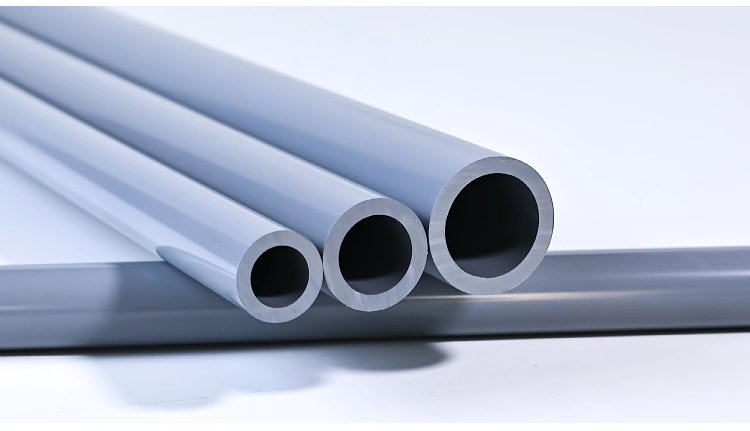

Product Overview

UPVC industrial pipes conforming to American standards are manufactured from high-purity rigid polyvinyl chloride (PVC) raw material, meeting ASTM D1785 specifications. With nominal outer diameters ranging from 15 to 315 mm and an operating temperature range of -10°C to 45°C, the 15 mm Sch.40 specification achieves a pressure rating of 1.6 MPa. These pipes are designed to meet standardized transmission requirements for industrial low-pressure fluids.

Key Advantages

These pipes resist corrosive media including 20% hydrochloric acid and 30% sodium hydroxide. With an oxygen index ≥40%, they achieve Class B1 flame retardancy. Inner wall roughness is only 0.01mm, reducing fluid resistance by 25% compared to steel pipes; meets NSF/ANSI 61 hygiene standards, weighs 1/6 of steel pipes, and boosts installation efficiency by 40%, balancing corrosion resistance and cost-effectiveness.

Manufacturing Process

Utilizes UPVC resin with a polymerization degree of 1200-1600, formed via twin-screw extrusion at 165-185°C. Vacuum sizing to American precision standards (tolerance ±0.2mm) is followed by segmented spray cooling at 22-26°C. After in-line wall thickness and outer diameter inspection, pipes undergo hydrostatic testing at 1.8 times nominal pressure. Qualified pipes are cut and packaged.

Application Industries

Fine Chemical Production: Suited for low-pressure fluid transfer in fine chemical applications. Complies with ASTM standards, resists acid/alkali corrosion, and operates stably from -10°C to 45°C, ensuring precise delivery for fine chemical manufacturing.

Municipal International Projects: Used in low-pressure water supply/drainage systems for international municipal projects. Meets American standards, features smooth inner walls for low friction and easy installation, fulfilling standardized construction requirements for international projects.

Electronics & Semiconductor Industry: Complies with NSF/ANSI 61 sanitary standards for conveying pure water in electronics and semiconductor production, preventing water contamination and supporting precision manufacturing of semiconductor components.

Food & Beverage Processing: Meets hygiene standards and resists mild corrosion, suitable for low-pressure fluid conveyance in food and beverage processing. Residue-free inner walls ensure production safety.

Cross-Border Industrial Projects: Adapted for low-pressure fluid transmission in cross-border industrial settings, strictly adhering to American standards. Offers stable performance and strong compatibility, meeting standardized construction requirements for international projects.

Our customization services cover every aspect of your needs, including color options, spray codes, brass materials, fitting molds, functionality, brand logos, and packaging.

Our piping systems are developed together with you, based on your performance targets or design goals, to ensure the final product delivers both technical consistency and aesthetic appeal—across every stage of production.

We have our own production workshops and warehouses, equipped with complete production and quality inspection equipment.

FRP composite pipe

Product Showroom

Pipeline storage area

Pipe fittings storage area

CNAS laboratory

SZNY proudly stands as a trusted partner to globally renowned pipeline suppliers and leading brands. Our products reach over 80 countries and regions worldwide, backed by a robust domestic network of distributors and sales points across China, ensuring comprehensive product availability and full-service support.

某某行业改造

某某行业改造

某某行业改造

某某行业改造

Providing users with safe, durable, and intelligent industrial piping systems