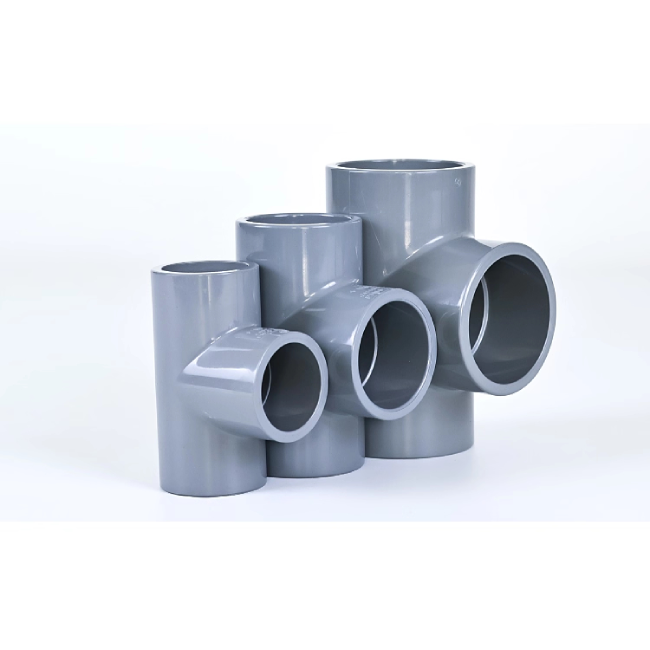

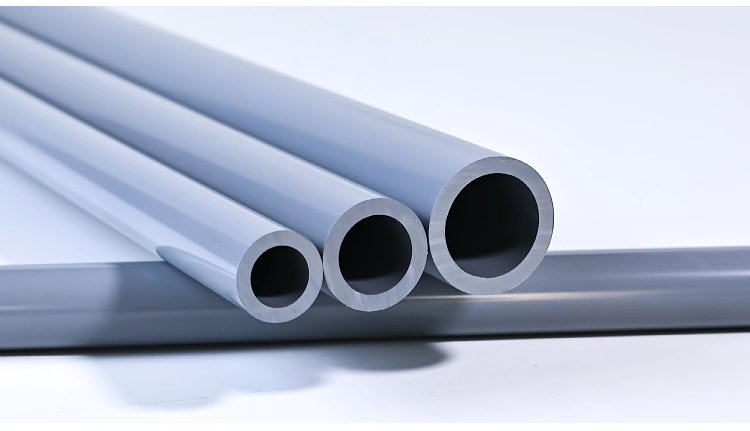

Product Overview

CPVC Tee Fittings are integrally injection-molded from high-purity chlorinated polyvinyl chloride (CPVC), compliant with GB/T 18993.2 standards. Available in nominal diameters from 20-200mm, they are compatible with CPVC chemical pipes of the same specification. Operating pressure ≤1.6MPa. with an inner wall smoothness of Ra ≤ 0.8μm, ensuring leak-free fluid diversion/convergence connections.

Fitting Features

Features a seamless, one-piece structure with tensile strength ≥ 55MPa and impact resistance ≥ 12kJ/m². Operates stably in environments from -40°C to 90°C, withstands corrosion from 95% sulfuric acid and 30% sodium hydroxide solutions; 98% material compatibility with pipes ensures high system pressure consistency post-connection; flame retardant with an oxygen index ≥40%; weighs only 1/5 of steel tees.

Manufacturing Process

CPVC resin with polymerization degree ≥1000 is selected. Precise injection molding at 185-205°C (mold tolerance ±0.05mm) is followed by gradient cooling at 25-35°C for shaping. The inner wall undergoes high-gloss finishing. Each fitting undergoes a 1.5x nominal pressure hydrostatic test (maintaining pressure for 30 minutes without leakage). Only qualified products are packaged and shipped.

Application Scenarios

Chemical Industry: Used for acid-alkali fluid diversion pipelines in chemical workshops. Resists high temperatures up to 90°C and strong corrosion, ensuring stable diversion at 1.6MPa pressure for efficient chemical production fluid transfer.

Pharmaceutical Industry: Suited for clean pipeline diversion of pharmaceutical intermediates. Meets GB/T 17219 hygiene standards with zero impurity residue and reliable sealing, safeguarding pharmaceutical production purity.

Electronics Industry: Connects electronic chemical circulating water diversion pipelines. Resists chemical corrosion with strong high-temperature stability, prevents water contamination, and meets electronic component cooling demands.

Electroplating Industry: Used for diverting electroplating waste liquid pipelines, withstanding strong corrosion from waste liquids. Its monolithic structure resists aging, reduces leakage risks, and supports environmentally friendly treatment processes.

Industrial Water Supply: Suitable for diverting industrial hot and cold water pipelines, providing stable connections within a temperature range of -40°C to 90°C and withstanding 1.6MPa pressure, meeting industrial hot and cold fluid distribution needs.

Usage Precautions

Clean pipe fittings and outer surfaces before installation to remove impurities. Use dedicated CPVC adhesive for bonding, adjusting curing time by pipe diameter (5-10 seconds for 20-63mm; 15-20 seconds for 75-200mm). Avoid prolonged exposure to temperatures exceeding 90°C (184°F) or pressures exceeding 1.6MPa (21.6 psi). Refrain from applying stress within 24 hours after installation. Periodically inspect bonded joints; replace immediately if leakage is detected.