Lugar de origen: China

Nombre de la marca: NULL/OEM

Técnicas: Forjado

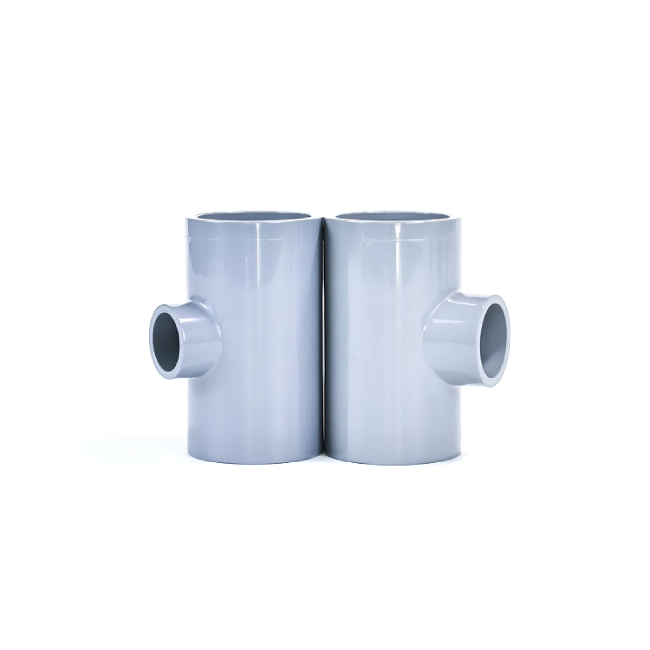

Conexión: Hembra, Enchufe

Forma: Reductora

Código de cabeza: Redondo

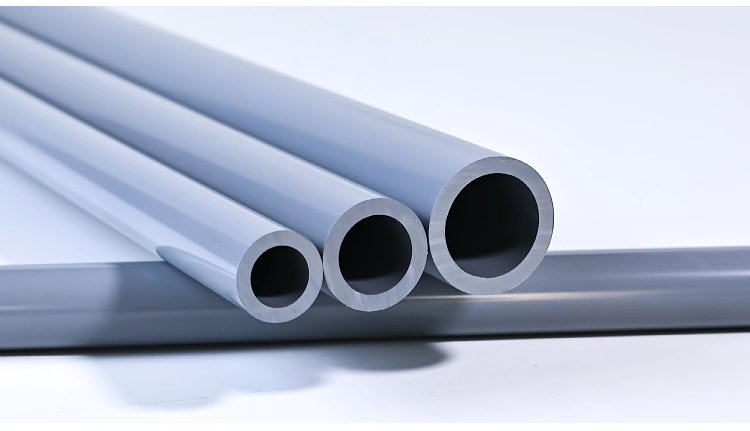

Color: gris

Aplicación: Industrial y Químico

Material: PVC

Tiempo de entrega: 7 días

Cantidad mínima de pedido: 1 pieza

Capacidad de suministro: 10000 piezas/piezas por mes